How to Solder connections on a CPE

I took apart the glove box and found one of the clip on connectors had nearly eaten through the wire  . So I decided to fix them all the correct and suggested way by CPE. So if you are in my boat or want to prevent this I took some pics of how to easily solder all CPE connections. While still making it easy to remove and not permanently change anything so it is easy to go back to stock.

. So I decided to fix them all the correct and suggested way by CPE. So if you are in my boat or want to prevent this I took some pics of how to easily solder all CPE connections. While still making it easy to remove and not permanently change anything so it is easy to go back to stock.

*************************************************************

Soldering iron and solder

Heat shrink wrap assorted sizes

Heat source

female spade lugs blue and red

Wire strippers and cutters.

*************************************************************

After removing ONE connector ONLY one you don't want 6 wires with no place to connect

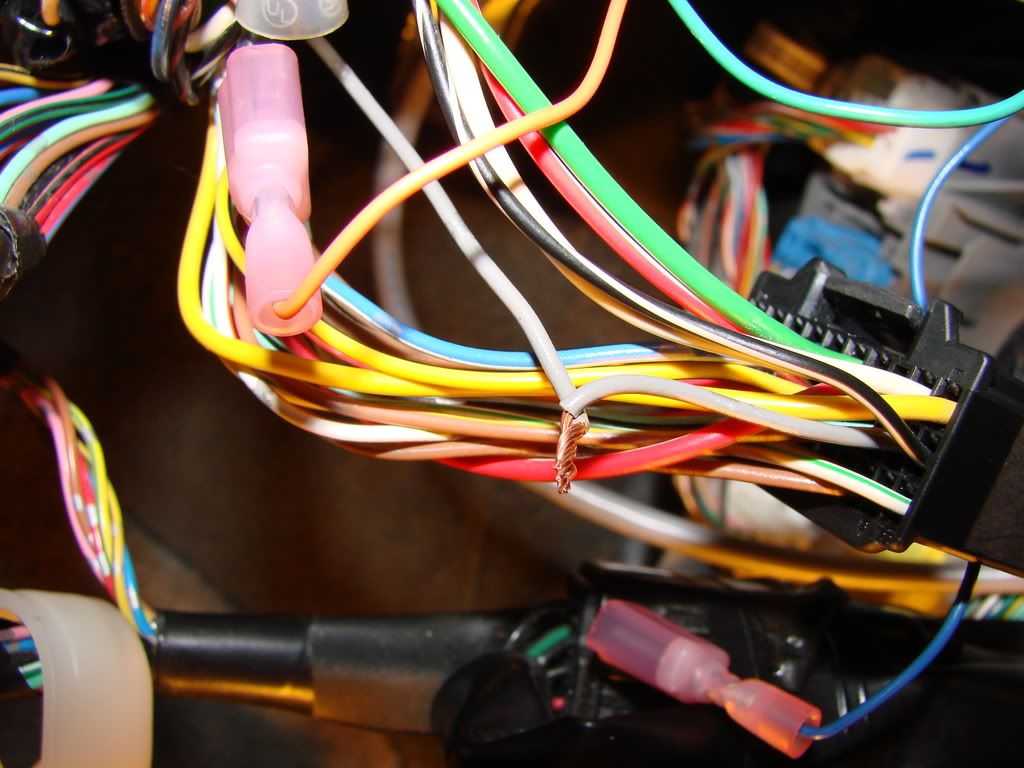

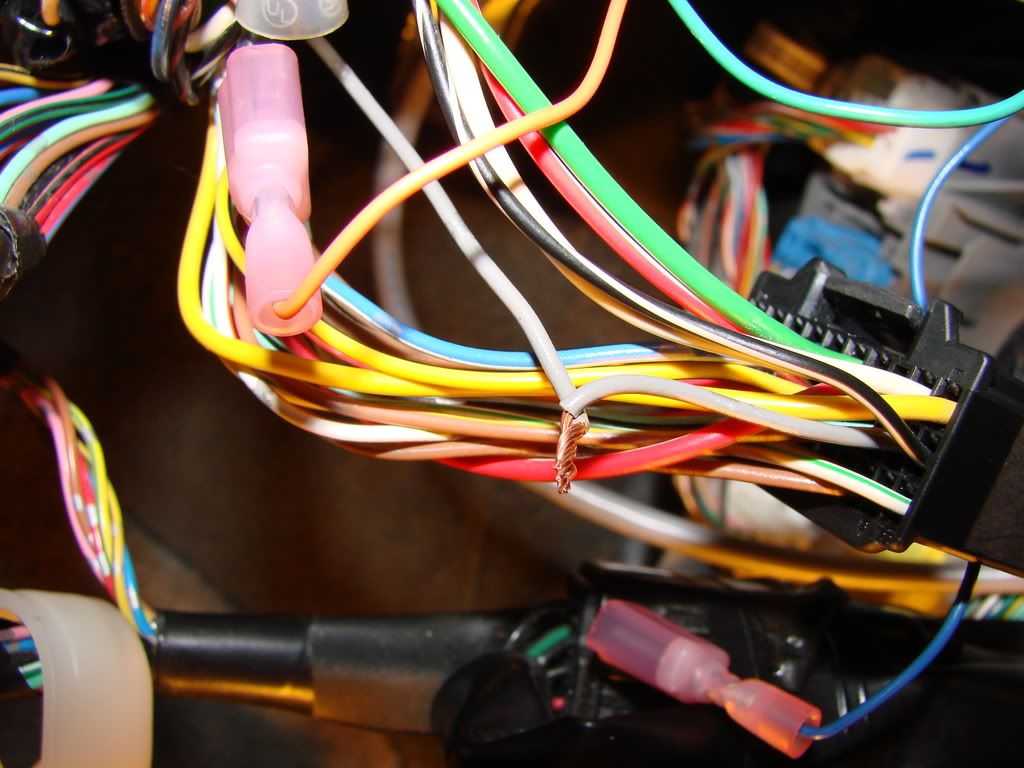

Start by striping the wires and twisting them together.

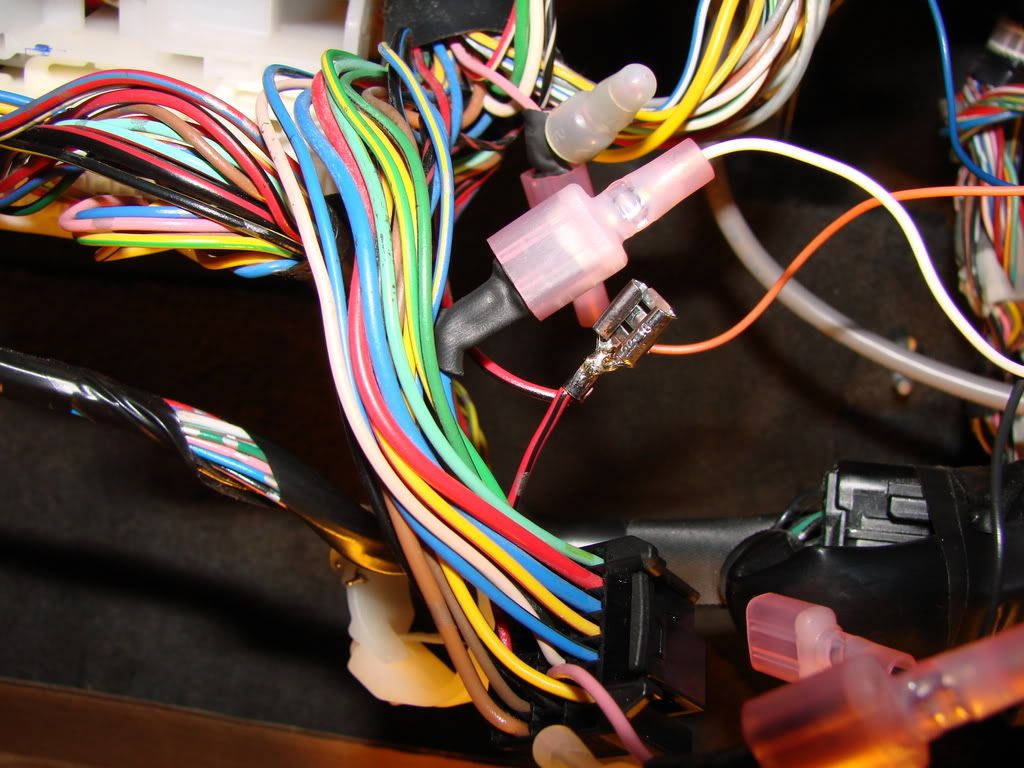

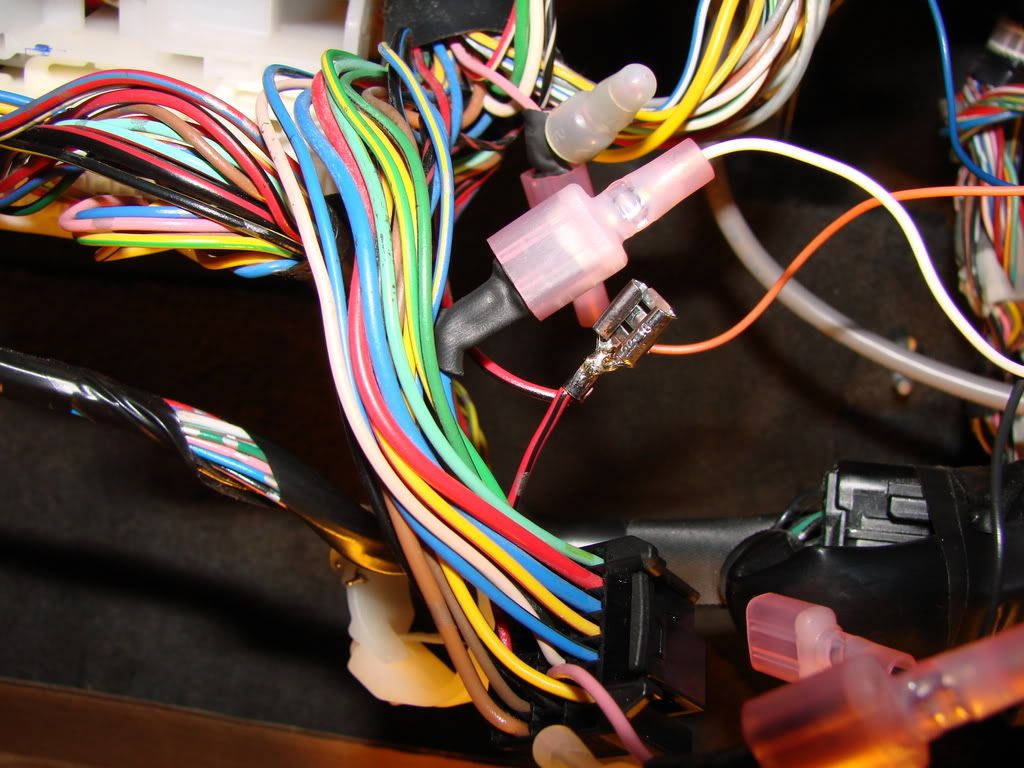

Then slip a spade female connector over it and solder it on NOT CRIMP solder it.

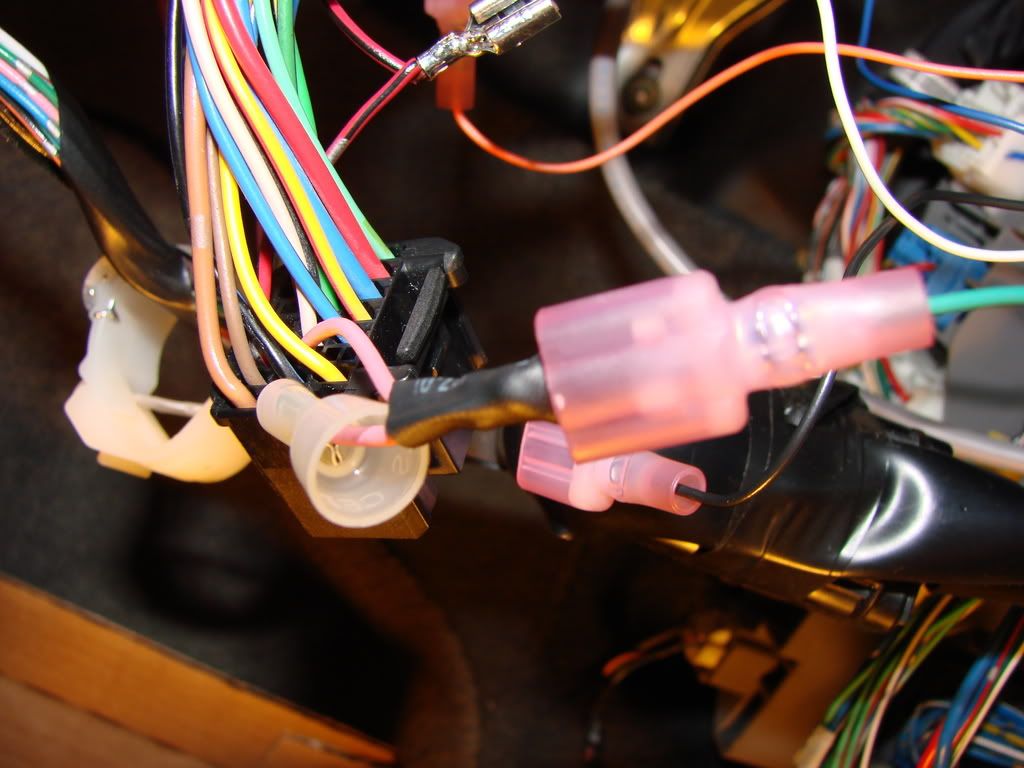

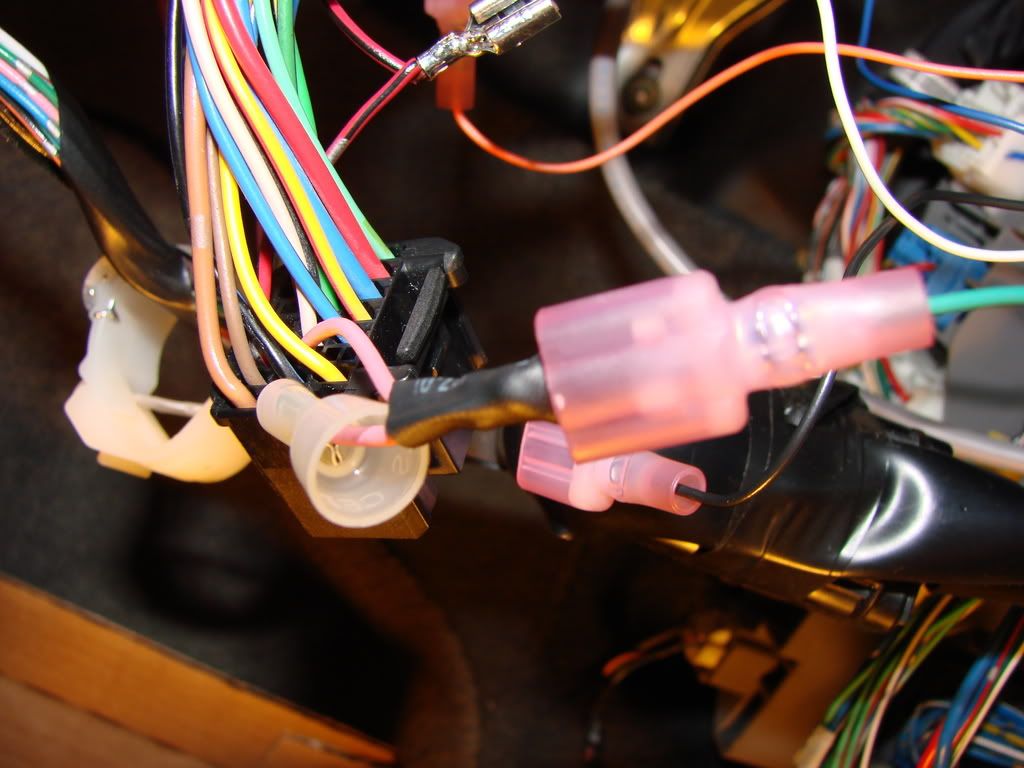

Next slip heat shrink tubing over it and apply heat. I used a small lighter.

Now just slip in the CPE connector

Here all finished

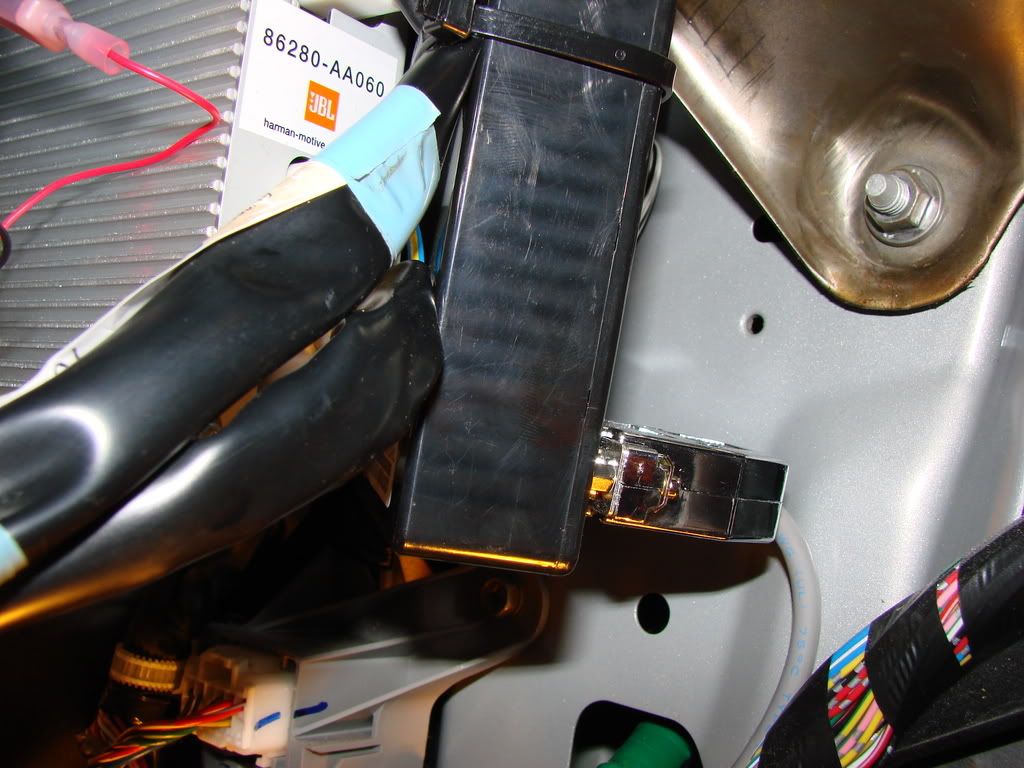

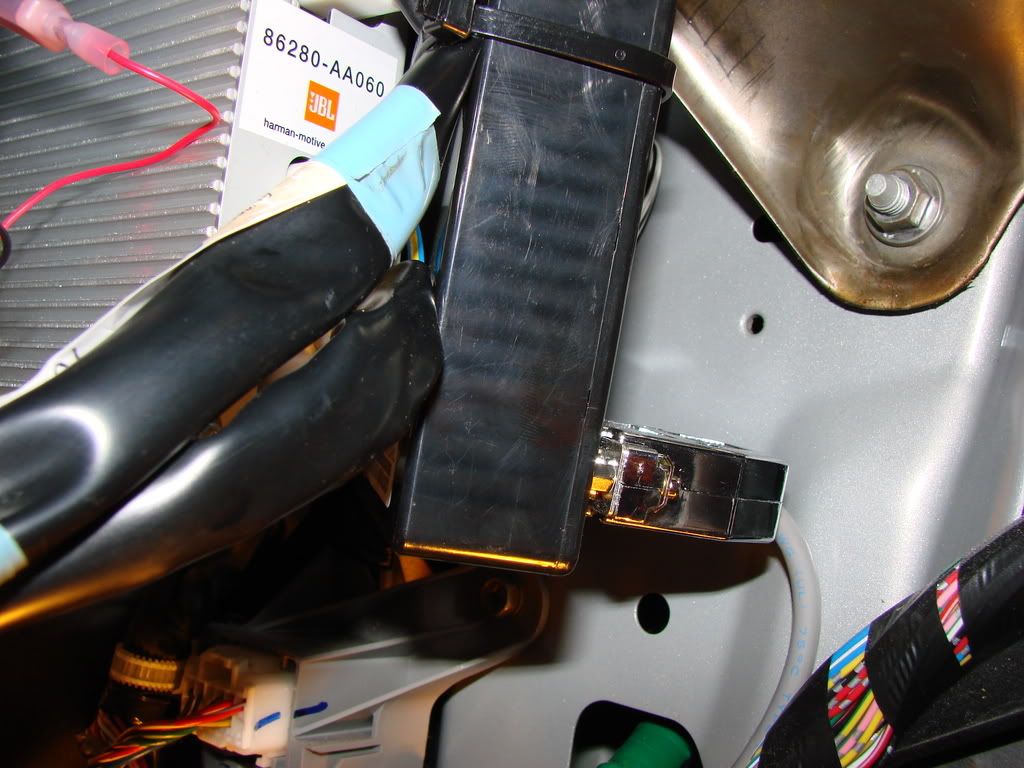

and the black box

*************************************************************

Soldering iron and solder

Heat shrink wrap assorted sizes

Heat source

female spade lugs blue and red

Wire strippers and cutters.

*************************************************************

After removing ONE connector ONLY one you don't want 6 wires with no place to connect

Start by striping the wires and twisting them together.

Then slip a spade female connector over it and solder it on NOT CRIMP solder it.

Next slip heat shrink tubing over it and apply heat. I used a small lighter.

Now just slip in the CPE connector

Here all finished

and the black box

-

Midias - SolaraGuy Semi-Pro Racer

- Posts: 3550

- Joined: Sun Jul 18, 2004 8:06 pm

- Location: Rochester NY